Harrison L5 Lathe Manuals

Well ive brought a harrison l5 lathe from a high school 400km later and 2 broken strops its home! While im geting my workshop wired up im giving it s clean up and a general tidy up. Im in need of a manual and i can't seem to find one anywhere i believe its a 1959 model the last of the threaded spindle nose.

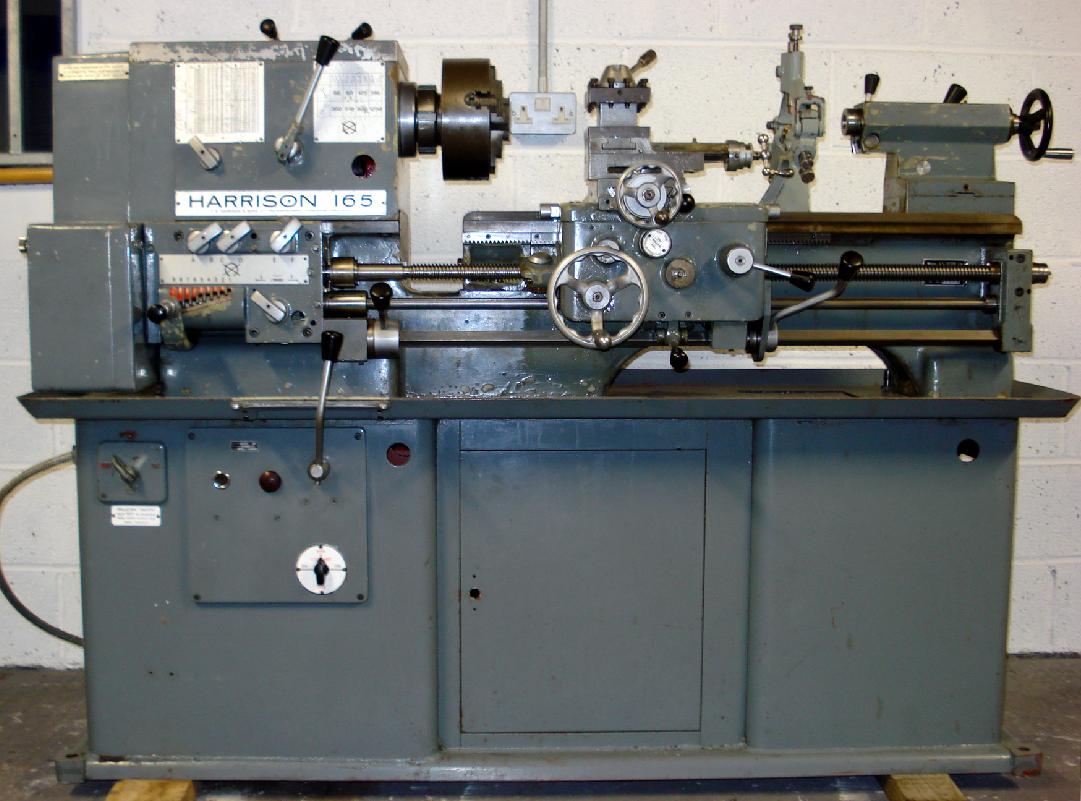

HARRISON LATHES L5A, (9' & 11') Later Models email: HARRISON LATHES L5A, (9' & 11') Later Models A manual for this lathe Newer Models: Lathes badged ' Harrison 11-inch ' are just machines produced during the last years of L5A/L6 production; they had a 5.5' centre height but, instead of a screwed thread on the spindle nose, were supplied as standard with the safer and more rigid American L00 (L zero-zero) fitting. Typical late-model Harrison badged as an '11-inch' and fitted with a full (Inch) screwcutting & feeds gearbox Harrison L5/L5A/11-inch with 3-speed screwcutting and feeds gearbox L5A/11-inch compound slide rest, 4-way toolpost on a T-slot top-slide, bed-mounted multi-stop and dial-thread indicator. Crossing Tijuana Border With Drivers License there. The changewheels were made from steel, not cast iron, and as a result could set up quite a ringing noise at higher spindle speeds; careful adjustment of backlash between mating teeth, and the use of a heavier, 'open-gear' lubricant helped to minimise this problem. L5A/11-inch carriage with the thicker top slide casting that allowed the use of a T-slot to retain the toolpost. This machine has the large bore, threaded headstock spindle. North American market L5A/11-inch badged as a 'Clearing' When the increased centre height L.5A was introduced its spindle (with a slightly larger 1.375' (35 mm) hole was also offered on the smaller machine L5 - though this is rarely found.

Email: HARRISON LATHES L5A, (9' & 11') Later Models A manual for this lathe Newer Models.

Sikhi 2 Max A Gurbani Software Download. Thanks lads, Brian as you say you push the clutch lever the opposite way to the drive position and it presses that disc against a thick steel collar that is on the gear shaft, I have never used it as I did not know it was there and no mention of it in the flimsy excuse of a manual Harrison provided, no mention of how to set up change wheels etc in it either. If you look at Keith Fenners videos on Youtube, he has a similar set up on his Colchester lathe and uses it quite a bit. Glad people are enjoying the thread anyway. Well at last some real progress on the lathe. From looking pretty much stripped right down again. The mission was to get this lot back inside the headstock All the gears have been de burred, new spindle bearings and new oil seals, a couple of gears that had chipped teeth replaced and everything cleaned and checked over.